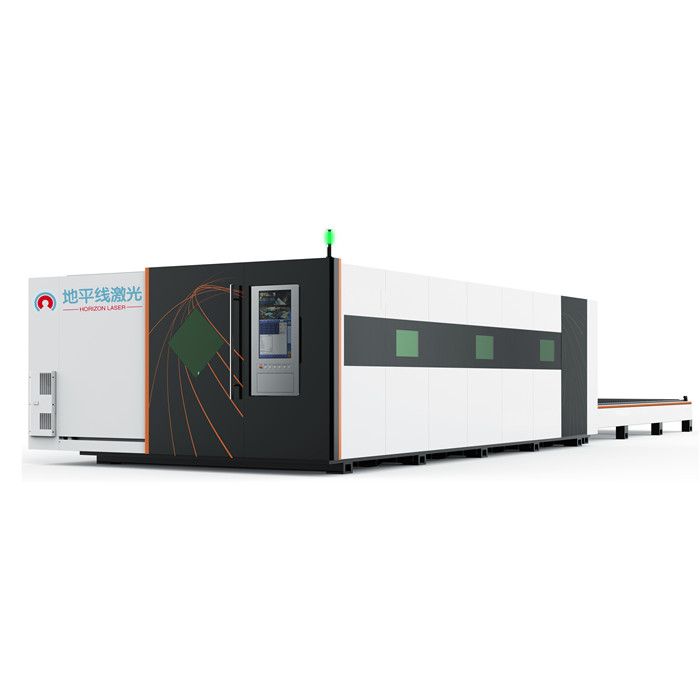

2021 China New Design China Laser Welding Machine - Multi-axis laser welding machine – Horizon

2021 China New Design China Laser Welding Machine - Multi-axis laser welding machine – Horizon Detail:

Technical Parameters

| Laser | CW fiber laser, QCW laser |

| Laser power | 1000-6000W |

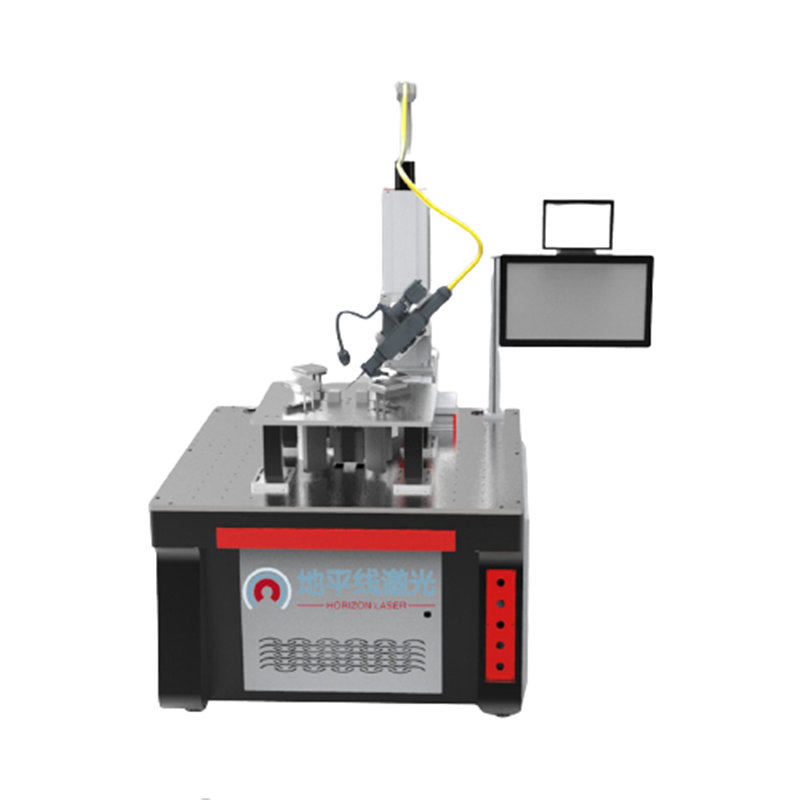

| Motion axis | 4- axis ( 3- axis, 5- axis, 6- axis optional), rotation axis |

| Welding head | Conventional welding head, swing welding head (weld seam 0.2 ~ 5 mm ) |

| Welding mode | Continuous welding (sealed welding, stitch welding, tailor welding, fillet welding), spot welding |

| Processing range | Length, width and height: 200-900mm (larger size can be customized) |

| Drive method | Servo motor (linear motor optional) |

| Repeatability | ± 0.03mm |

| Other optional configuration | Double station, CCD positioning, conveyor belt loading and unloading machine, wire feeding mechanism |

Features

Servo motor is matched with reducer to realize high-speed and large-torque movement;

Simultaneous multi-axis linkage to achieve a processing track similar to that of a manipulator;

The matching material tray can realize large-scale and batch one-time welding; the open IO handshake interface can be processed with automated production lines.

welding is 4 times faster than argon arc weldingl;

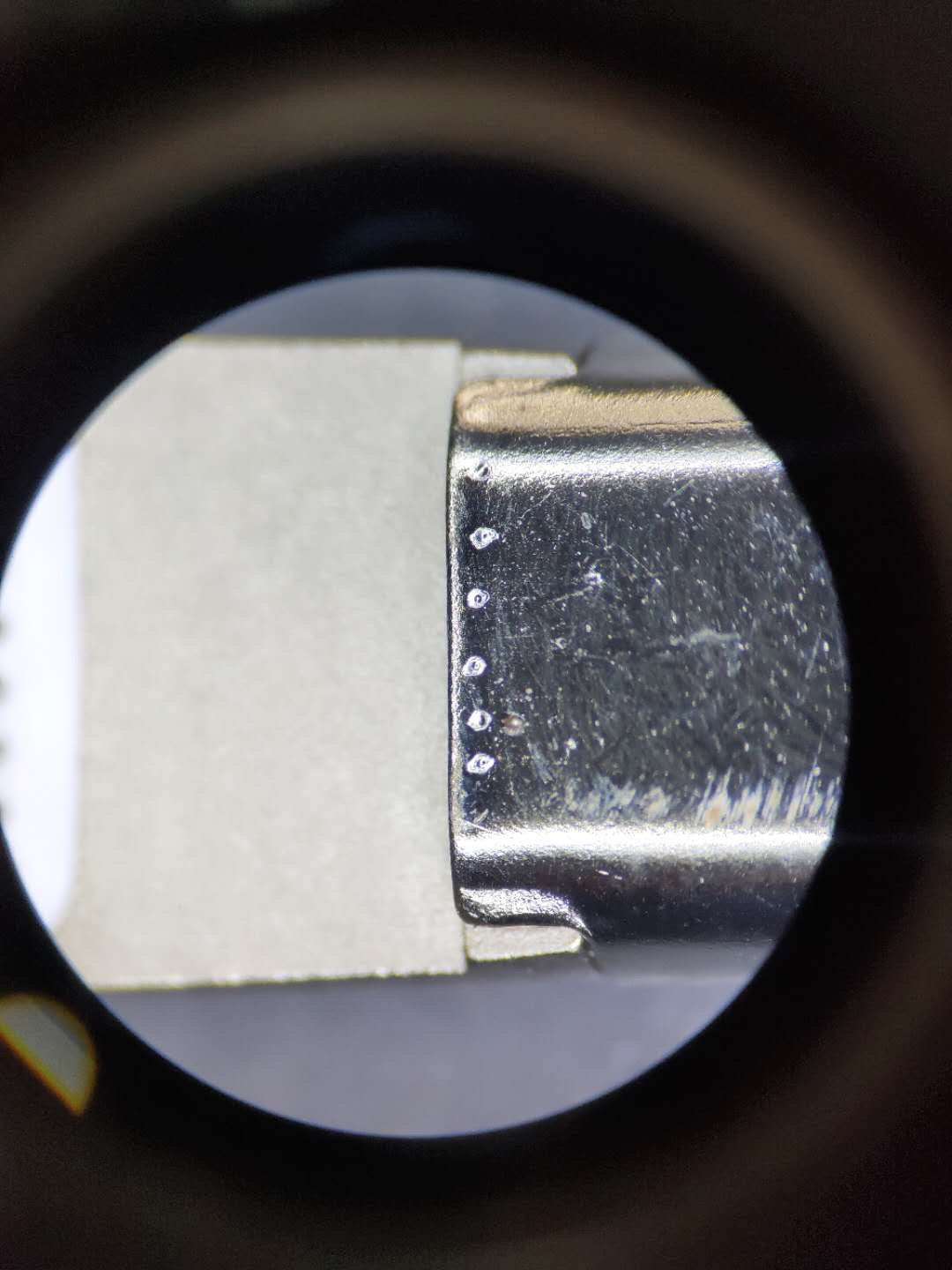

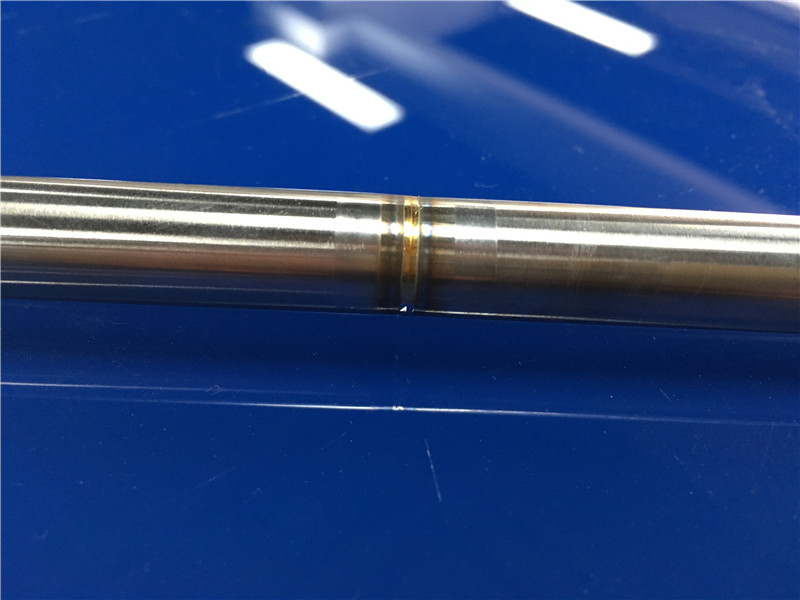

One-time welding forming, smooth welding bead, no need for grinding;

Basically no consumables, standardized use, the protective lens can be used for several weeks;

You can get started in 4 hours and become skilled as an professional welder in one day;

Comes with air pressure detection alarm to avoid damage to the welding torch;

Apply effects

It has a high degree of flexibility and can meet the welding needs of any complex work piece. It is widely used in the automotive industry and electrical cabinet industry.

Our Service

The company provides customers with accurate, effective and fast services.

Pre-sale: The company’s sales and technical service personnel participate in the customer proofing, model selection, and process testing processes, and provide comprehensive technical advice and support for customers to determine purchases;

Product detail pictures:

Related Product Guide:

We've been proud with the significant shopper fulfillment and wide acceptance due to our persistent pursuit of top of the range both of those on solution and repair for 2021 China New Design China Laser Welding Machine - Multi-axis laser welding machine – Horizon , The product will supply to all over the world, such as: Saudi Arabia, Haiti, Washington, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to offer you good quality products and the best service. We are looking forward to serving you.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Products categories

-

E-mail

-

WhatsApp

-

Wechat

Wechat

18823836110

-

Top