Single Table

Exchange Table

1. Cutting effects

1.1 Carbon steel cutting effect

Carbon steel cutting effect, divided into two: bright surface and frosted surface.

Bright surface: cutting section smooth, glossy effect, small taper, high laser power required;

Frosted surface: the cutting surface is rough, abrasive effect, large taper, low laser power required.

6000W:16-25mm frosted surface

12kW:16-25mm bright surface

|

Power |

1000W |

1500W |

2000W |

3000W |

6000W |

8000W |

12kW |

20kW |

|

Maximum bright thickness |

3mm |

4mm |

6mm |

8mm |

12mm |

16mm |

25mm |

30mm |

1.2 Stainless steel cutting effect

Stainless steel cutting effect, divided into three kinds: hanging slag, hanging slag, layering.

No hanging slag effect: delicate section, no hanging slag at the bottom. The higher the laser power, the thicker stainless steel without hanging slag effect can be cut;

Hanging slag effect: delicate section, the bottom slightly hanging slag or serious hanging slag. Limit cutting thickness will appear slag hanging phenomenon, in addition to cutting pressure is insufficient or cutting focus is not appropriate will also appear slag hanging phenomenon;

Stratification effect: sectional stratification, inconsistent. Section delamination occurs when cutting pressure is insufficient, cutting focus is inappropriate or cutting speed is too fast.

No hanging slag

Hanging slag

Stratification

2. Power selection procedure of fiber laser cutting machine

Material→Thickness→Effect→Efficiency

Nitrogen cutting (stainless steel/carbon steel) basically no taper, suitable for cutting holes, sharp corners and other graphics.

Oxygen cutting carbon steel, abrasive surface taper, sharp Angle over burning serious, not suitable for cutting holes; Bright surface basically no taper, suitable for cutting holes.

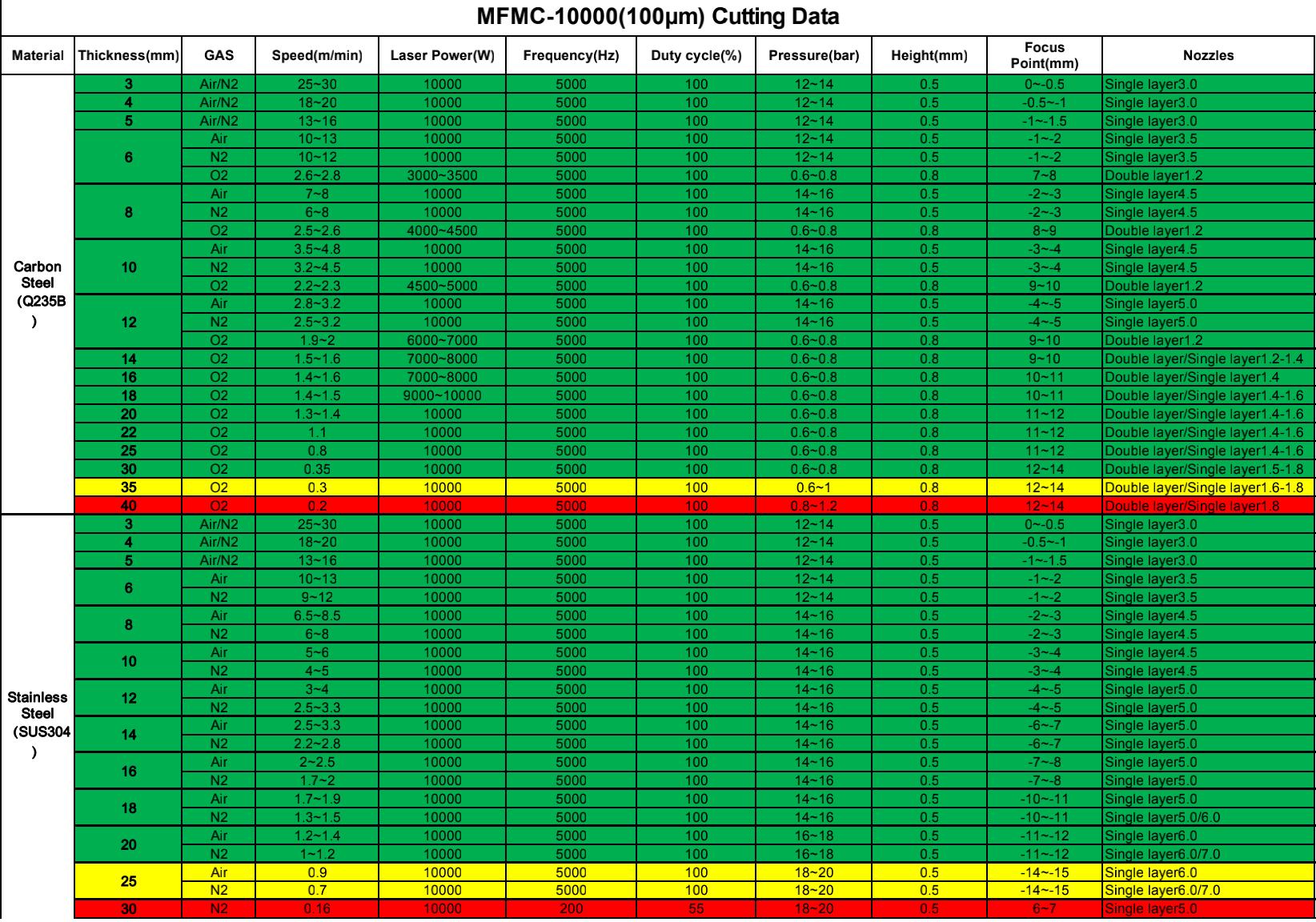

3.Cutting parameters

Post time: Oct-18-2022