NEW PRODUCT

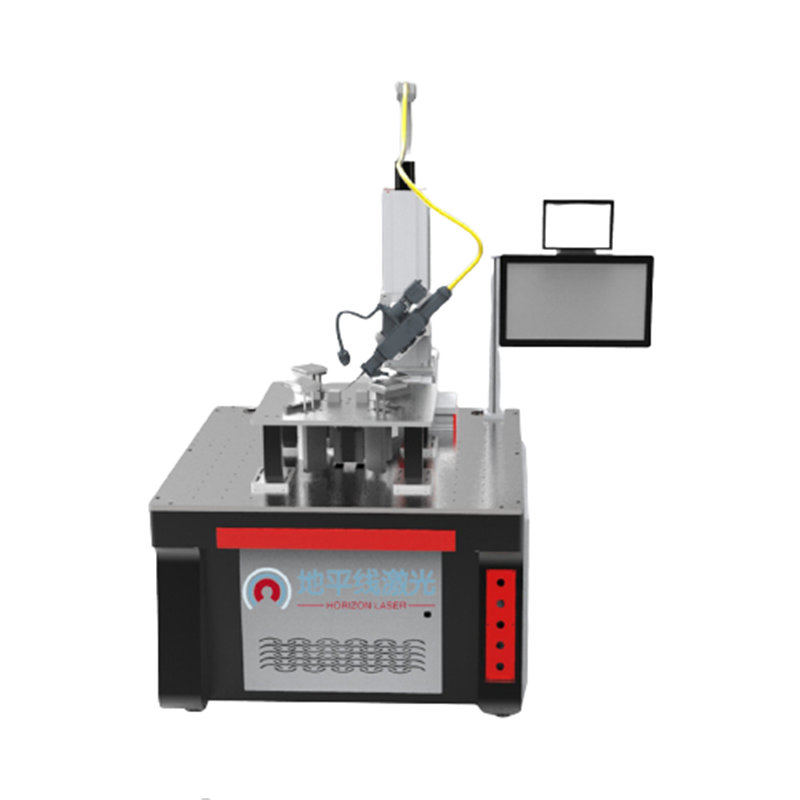

Air cooled handheld laser welding machine

The air-cooled handheld laser welding machine is a high-power laser welding device newly launched by Horizon Laser Technology Co., Ltd. The entire machine adopts an air-cooled structure, with a compact size and easy mobility, meeting the needs of more application scenarios. The handheld mode facilitates the welding of products such as boilers, cabinets, doors, windows, and advertising signs, making laser welding possible for outdoor operations. It is set to replace most applications of traditional electric welding and argon arc welding. The air-cooled handheld laser welding machine integrates an air-cooled laser, handheld welding gun, wire feeder, laser control system, and safety light emission system into one unit. It can stably and continuously emit light for welding, enabling butt welding, lap welding, seal welding, seam welding, and spot welding of products.

WITH YOU EVERY STEP OF THE WAY.

From selecting and configuring the right

machine for your job to helping you finance the purchase that generates noticeable profits.

fast

Service

The company provides customers with accurate, effective and fast services.Pre-sale: The company’s sales and technical service personnel participate in the customer proofing, model selection, and process testing processes, and provide comprehensive technical advice and support for customers to determine purchases;

The company will assist customers in completing the selection and integration of the sub-modules of the whole machine, as well as the debugging and process. Also can provide training for customer’s technical staff; on product knowledge, application schemes, common problems and troubleshooting.

recent

NEWS

-

E-mail

-

WhatsApp

WhatsApp

-

Wechat

Wechat

18823836110

-

Top