Leverage Horizon Laser’s cutting-edge technology and industry expertise—from early-stage proofing to final product delivery. Whether it’s laser cutting, welding, or cleaning, we customize high-performance systems to match your unique needs with full lifecycle technical support.

Discover advanced, fully integrated laser technologies designed around your specific manufacturing challenges. At the intersection of photonics and intelligent automation, our systems empower you to:

Eco-friendly, contactless cleaning technology to remove rust, paint, oil, and surface contaminants without damaging the base material.

Seamless and durable welding solutions powered by advanced laser control and automation. Perfect for precision assemblies in demanding industries.

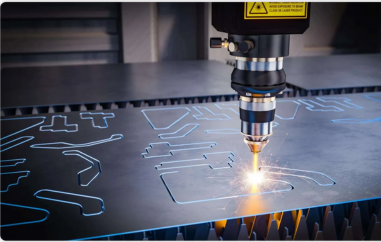

High-speed, high-accuracy laser cutting services tailored for diverse materials and applications. Ideal for both prototyping and mass production with optimized efficiency.

From module selection to process debugging, we provide complete OEM laser system integration backed by senior technical experts.

Horizon Laser is pleased to announce its participation in CLEANING EXPO UK 2026, taking place on March 27–28, 2026, at NAEC Stoneleigh Park, Warwickshire (CV8 2LZ), Midlands, UK. As a leading provider

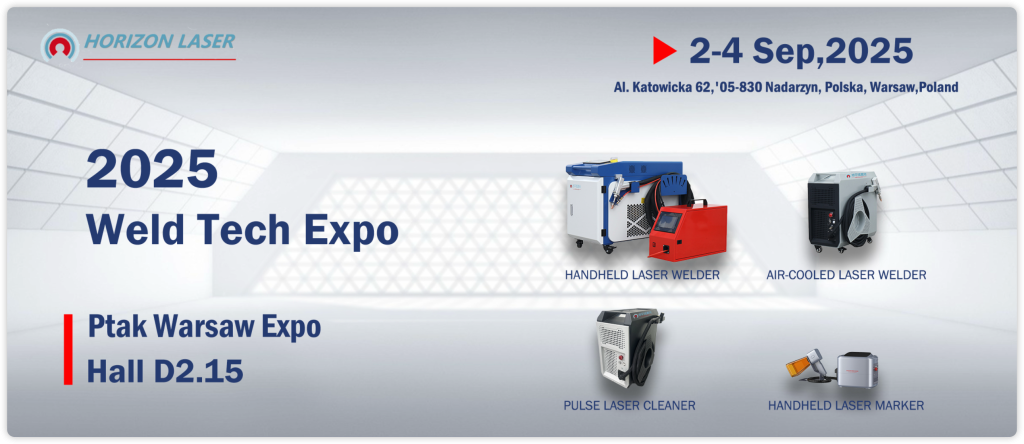

Horizon Laser is proud to announce its participation in the Welding Technology Exhibition 2025, which will take place from September 2–4, 2025, at the PTAK Warsaw Expo, Poland. We warmly welcome visitors

Horizon Laser is pleased to announce its participation in the Tire Technology Expo 2026, taking place from March 3–5, 2026 at Hannover, Germany. Visitors can find us at Hall 20 Stand 4027,

From November 12–15, 2025, Horizon Laser will participate in CMES Vietnam 2025, held at the Vietnam Exposition Center (VEC), Hall B12, Hanoi, Vietnam. As one of the leading providers of industrial laser

Exhibition Date: September 2–4, 2025Booth Location: Ptak Warsaw Expo, Booth D2.15 We are excited to announce that Horizon Laser will be participating in the WELD TECH EXPO 2025, taking place at the

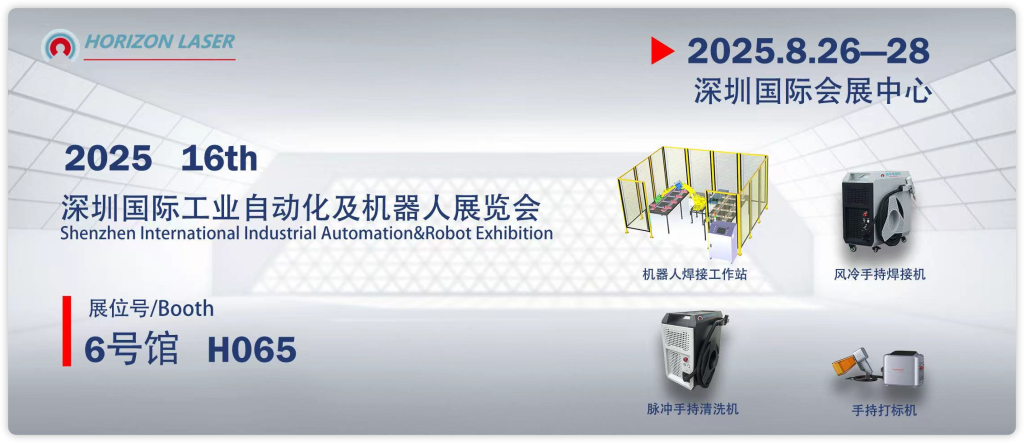

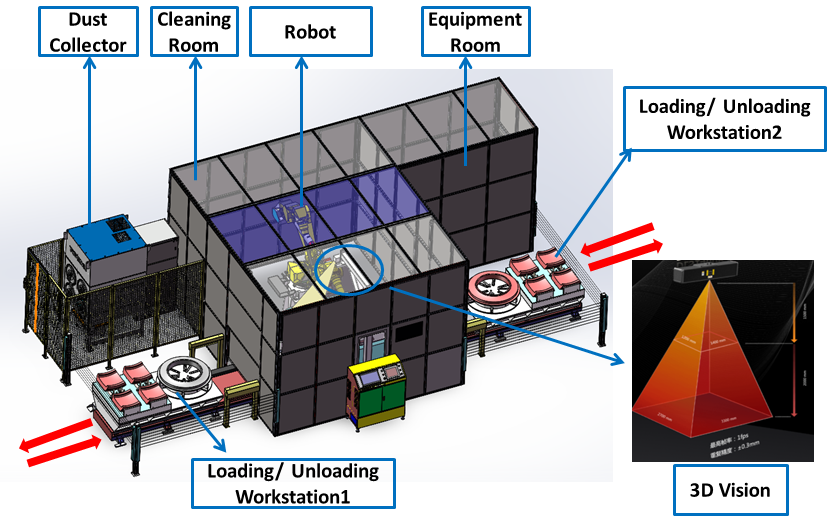

As artificial intelligence, big data, and industrial automation continue to converge, the global manufacturing industry is accelerating its transformation toward intelligent, efficient, and flexible production. As a leading innovator in laser-based intelligent

We’re your trusted partner in precision laser cleaning—from initial testing to full-scale application. Horizon Laser helps you accelerate surface preparation with non-contact, eco-friendly laser cleaning technology. Whether you’re removing rust, paint, oil, or coatings, our expert team provides full-cycle support to optimize your process for cost, efficiency, and material integrity. Ready for production? We’ll help you scale with confidence.

Tell us about your needs, and material specifications. Our team will analyze your goals and start shaping the right laser solution for you.

We provide tailored model recommendations, proofing samples, and process testing based on your requirements.

Our engineers will design and integrate modular laser systems to meet your production goals.

Once delivered, we provide full technical training and on-site or remote support. You also get long-term after-sales service.

With every inquiry, you’ll receive tailored technical advice and process analysis to improve system performance and reduce cost. If you have further questions, our senior engineers are ready to assist with application guidance, equipment selection, and integration planning. Reach out anytime at +86 18823836110 Email:info@dpxlaser.com

Horizon Laser Technology Co., Ltd is a new high-tech enterprise integrating technical services, technology promotion, laser equipment modular design, sales and integration services.

Floor 6, Building 4, Huidongsheng Industrial Park, No. 1028 Guangqiao Avenue, Yutang Street, Guangming District, Shenzhen, China

© 2025 Horizon Laser. All Rights Reserved.

Designed by AdmarV