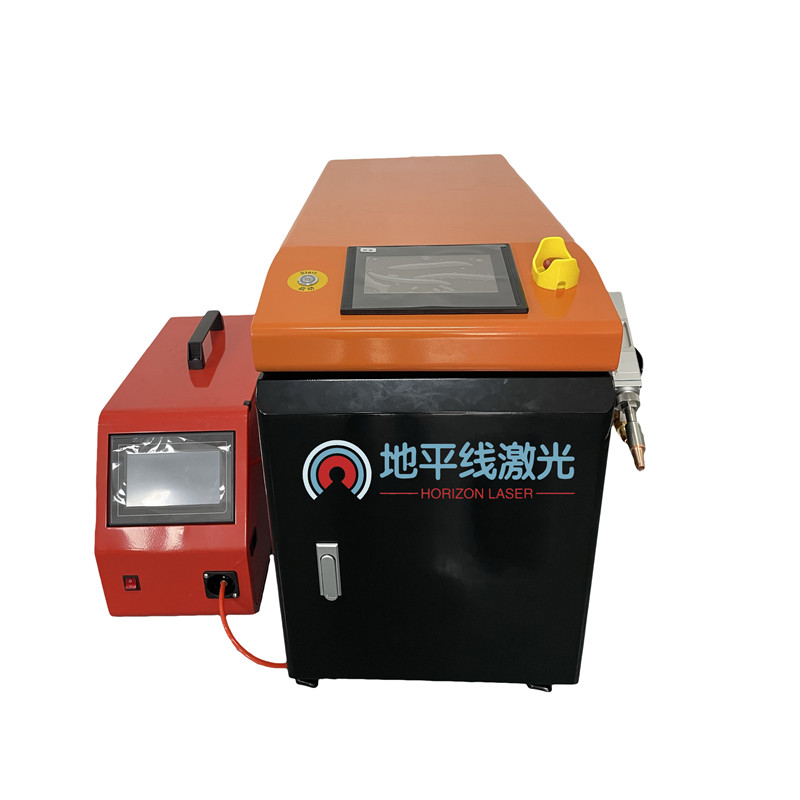

China Cheap price Laser Marker - Laser marking machine series – Horizon

China Cheap price Laser Marker - Laser marking machine series – Horizon Detail:

Features

1.It can be used to process a variety of metals, non-metallic (effect depending on lasertype) material, especially for high hardness, high melting point, brittle materials, more obvious advantages.

2, It is a non contact processing, does not damage the product, no tool wear, with high marking quality.

3. Laser beam is very small, and the material consumption is very small, and the processing thermal influence area is small.

4. The processing efficiency is high, the use of computer control, easy to realize automation.

Advantages

● All kinds of metal materials and some non-metallic materials marking

● Air cooling system, no maintenance

● Free to change the marking parameters and graphics

● Stable working performance, life time can reach 100,000 hours

● Marks are anti-falsification, more fine and unique

Desktop marking machine

Hand-held marking machine

Mini marking machine

Portable Marking Machine

Marking machine Technical parameters

| power: | 20w/30w/50w |

| laser wavelength | 1064nm |

| makring area | 100*100m |

| optional marking area | 110*110mm/1 50*1 50mm/200*200mm |

| marking speed | 8000mm/second |

| minimum line width | 0.012mm |

| minimum character | 1.5mm |

| repeated precision | 0.003mm |

| life-span of fiber laser module | 100.000 Hours. |

| beam quality | m2<1.5 |

| focus spot diameter | <0.001 mm |

| output power of laser | 10%-100%continuously to be adjusted |

| system operation environmen | windows xp/wind7/wind8 |

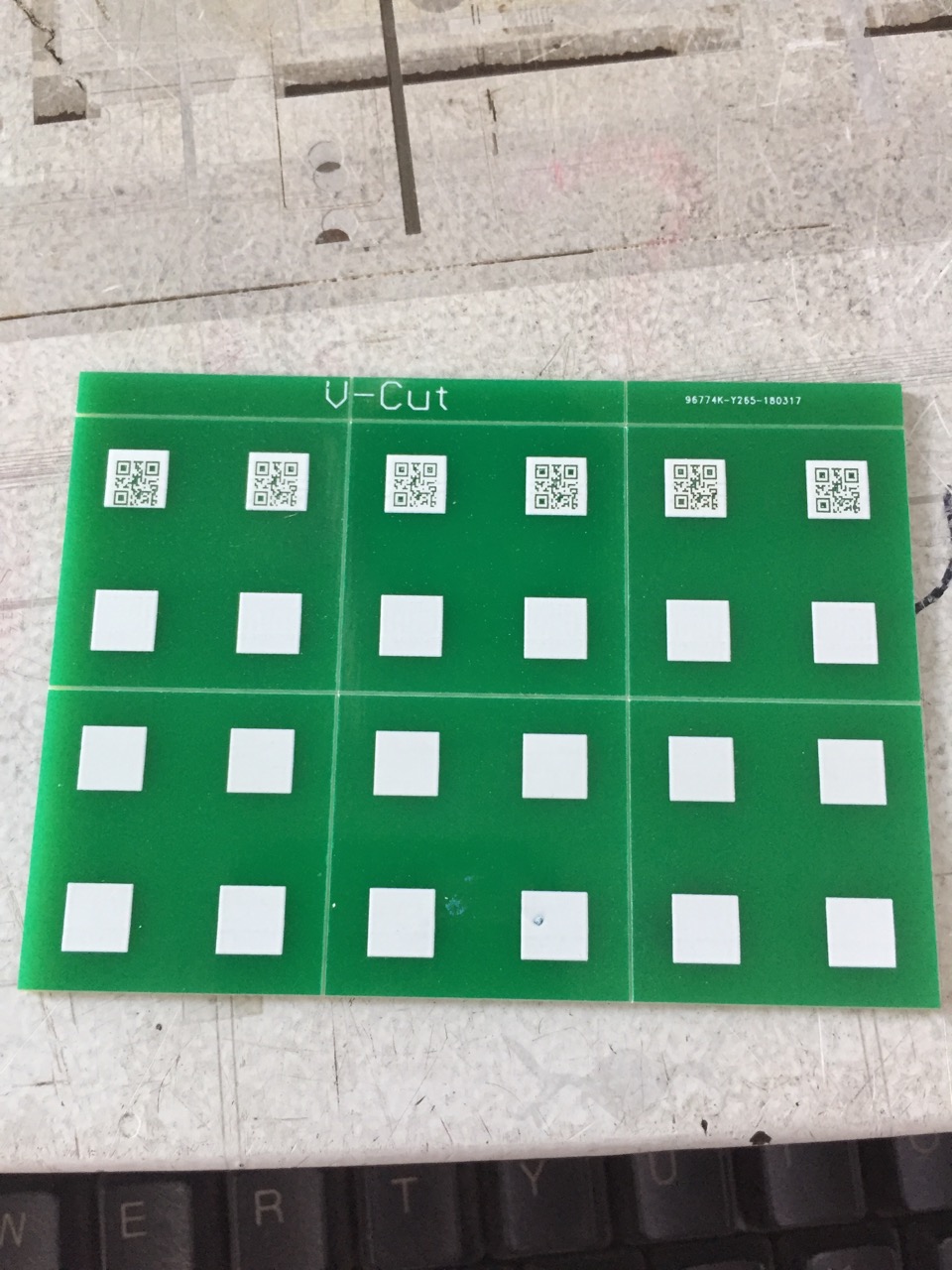

Application effect

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto "High Quality, Competitive Price, Fast Service" for China Cheap price Laser Marker - Laser marking machine series – Horizon , The product will supply to all over the world, such as: Puerto Rico, Victoria, Puerto Rico, We are increasingly expanding our international market share based on quality products, excellent service, reasonable price and timely delivery. Please contact us at any time for more information.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

Products categories

-

E-mail

-

WhatsApp

-

Wechat

Wechat

18823836110

-

Top