News

-

100-300W PULSE FIBER LASER CLEANING MACHINE

Pulse fiber laser cleaning machine adopts pulse fiber laser source, a new generation of non-contact cleaning equipment. The high-brightness laser is transmitted through the optical fiber, and combined with the hand-held cleaning head, it can flexibly swing and clean. The...Read more -

50W-100W BACKPACK LASER CLEANING MACHINE

The backpack laser cleaning machine has the characteristics of small size, light weight, and easy portability. The cleaning operation is not limited by the scene. Matching the mobile power supply, it can realize the laser cleaning of outdoor products. The high-brightness...Read more -

How to choose the most suitable power fiber laser cutting machine?

Single Table Exchange Table 1. Cutting effects 1.1 Carbon steel cutting effect Carbon steel cutting effect, divided into two: bright surface and frosted surface. Bright surface: cutting ...Read more -

Cutting Process Debugging Method for Laser Cutting Machine

Note: Before debugging the cutting process, it is necessary to prepare the required cutting and debugging: nozzle, protective lens, plate, gas (N2, O2), clean workbench, microscope. Materials Material Grade Stai...Read more -

Parameter Adjustment Guide for Handheld Laser Welding Machine

Follow these principles when welding: ①The thicker the plate, the thicker the welding wire, the greater the power, and the slower the wire feeding speed. ②The lower the power is, the whiter the welding surface will be, and the higher the power ...Read more -

Maintenance and replacement of hand-held laser welding head lens

Regarding the maintenance and replacement of all the following lens, clean cloth and absolute ethanol (purity > 95%) should be prepared in advance. When operating in a relatively dust-free environment (office), you need to contact the manufa...Read more -

Common Problems and Solutions for Handheld Laser Welding Machines

1.Burn of protective lens Performance: In a short period of time, the protective mirror is damaged and there is a burning spot, and the light-emitting surface of the protective mirror is dotted with damaged spots, showing black spots. Cause Ana...Read more -

Red beam & Focus Adjustment for Handheld Laser Welding Machine

First:Red beam adjustment Normal Offset 1. If the red beam is slightly shifted left and right, you can set the offset ...Read more -

Selection guide for laser cleaning machine

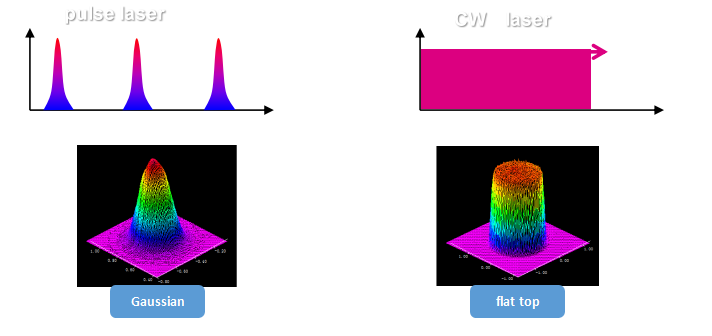

Step 1: Select the laser type of cleaning machines 1. Pulse laser: It can better control the heat input and prevent the substrate temperature from being too high or micro-melting. It is suitable for application scenarios with high precision, wh...Read more -

Comparison between pulse and CW laser cleaning machines

一、Comparison of parameters between pulsed laser and CW laser Pulse laser (for cleaning) CW laser Average Power Hundred-watts class(100-500W) Kilowatt class(1000-3000W) Peak Power 10K-watts class(10-40KW) Kilowatt class(1000-3000W) Lighting Method Pulse ...Read more -

How to improve the efficiency of fiber laser marking machine?

1-Factors Affecting Marking Efficiency For a fixed marking pattern, the factors affecting the marking efficiency can be divided into the equipment itself and processing materials. From these two factors, it can be subdivided into different aspects: Therefore, the filling type, field mirror (fi...Read more -

How to choose a suitable configuration of laser marking machine?

1. Switching power supply Now laser equipment manufacturers use two major brands of switching power supply: Mingwei (WM) and Hengfu (hf), but there are many counterfeit switching power supplies of big brands on ...Read more