Description

High-power (12000W-30000W)

Technical Parameters

| Laser power | 12000-30000W | |||

| Model | DPX-J6025 | DPX-J8025 | DPX-J10025 | DPX-J12025 |

| Cutting range | 6000 × 2500mm | 8000 × 2500mm | 10000 × 2500mm | 12000 × 2500mm |

| Cutting focus method | Auto focus | |||

| Machine running accuracy | Acceleration: 1.8G | |||

| Maximum speed: 150m/min | ||||

| Axial positioning accuracy of worktable: ± 0.05mm/m | ||||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | ||||

Cutting performance

| material | 12000W cutting performance | 15000W cutting performance | 20000W cutting performance | |||

| carbon steel | stable cutting | ≤ 35mm | stable cutting | ≤ 40mm | stable cutting | ≤ 45mm |

| Limit cut | 50mm | Limit cut | 60mm | Limit cut | 70mm | |

| Stainless steel | stable cutting | ≤ 30mm | stable cutting | ≤ 35mm | stable cutting | ≤ 40mm |

| Limit cut | 50mm | Limit cut | 70mm | Limit cut | 80mm | |

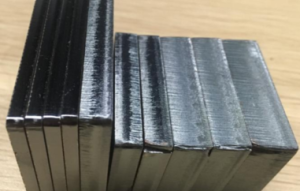

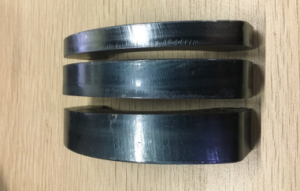

Application effect

Medium power (3000W-6000W)

Technical Parameters

| Laser power | 3000-6000W | |||

| Model | DPX-J3015 | DPX-J4020 | DPX-J6025 | DPX-J8025 |

| Cutting range | 3000 × 1500mm | 4000 × 2000mm | 6000 × 2500mm | 8000 × 2500mm |

| Cutting focus method | Auto focus | |||

| Machine running accuracy | Acceleration: 1.2G | |||

| Maximum speed: 100m/min | ||||

| Axial positioning accuracy of worktable: ± 0.05mm/m | ||||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | ||||

Cutting performance

| material | 3000W cutting performance | 4000W cutting performance | 6000W cutting performance | |||

| carbon steel | stable cutting | ≤ 20mm | stable cutting | ≤ 22mm | stable cutting | ≤ 25mm |

| Limit cut | 25mm | Limit cut | 25mm | Limit cut | 30mm | |

| Stainless steel | stable cutting | ≤ 9mm | stable cutting | ≤ 10mm | stable cutting | ≤ 14mm |

| Limit cut | 12mm | Limit cut | 14mm | Limit cut | 20mm | |

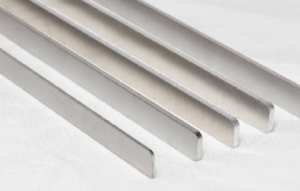

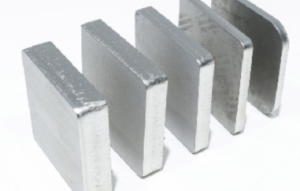

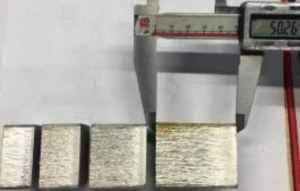

Application effect

Low power ( 1000-2000W )

Technical Parameters

| Laser power | 1000-2000W | ||

| Model | DPX-J3015 | DPX-J4020 | DPX-J6025 |

| Cutting range | 3000 × 1500mm | 4000 × 2000mm | 6000 × 2500mm |

| Cutting and focusing method | Manual / automatic focusing | ||

| Machine running accuracy | Acceleration: 1.0G | ||

| Maximum speed: 80m/min | |||

| Axial positioning accuracy of worktable: ± 0.05mm/m | |||

| Repeated positioning accuracy of worktable: ± 0.03mm/m | |||

Cutting performance

| Material | 1000W cutting performance | 1500W cutting performance | 2000W cutting performance | |||

| Carbon steel | stable cutting | ≤ 8mm | stable cutting | ≤ 12mm | stable cutting | ≤ 16mm |

| Limit cut | 12mm | Limit cut | 16mm | Limit cut | 20mm | |

| Stainless steel | stable cutting | ≤ 4mm | stable cutting | ≤ 6mm | stable cutting | ≤ 7mm |

| Limit cut | 6mm | Limit cut | 8mm | Limit cut | 10mm | |

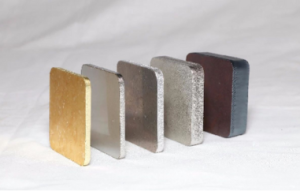

Application effect