Description

Features

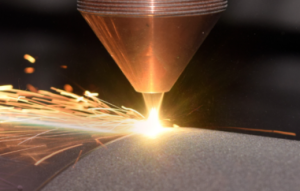

- It adopts a flat-top beam fiber laser, and the cladding effect is even and flat;

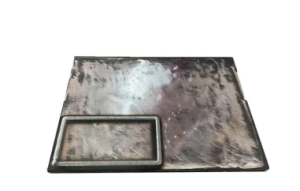

- The cladding width is adjustable 2-6mm, adapting to different product needs;

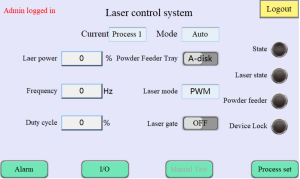

- The system integrates laser, powder feeder, and robot control to realize one-click start cladding;

- Double-barrel powder feeder can meet the uninterrupted cladding of large-sized components;

- It adopts a 4-way coaxial ring powder feeding match with a special powder divider, so that the powder feeding is more evenly;

- The amount of powder is matched with the spot size and laser energy, which can achieve different cladding thickness requirements.

Technical parameters

| Equipment Model | DPX-CL6000 | DPX-CL12000 |

| Laser Type | Fiber Laser (Wavelength: 1080±3 nm) | |

| Laser Power | 6000W | 12000W |

| Power Range | 10%~100% | |

| Beam Profile | Flat-top beam | |

| Cooling Method | Water cooling | |

| Robot Arm | 1.8m(optional) | |

| Beam Size | 2-6mm | |

| Powder Feeding | 4-channel coaxial annular powder feeding | |

| Powder Focus Distance | 15mm | |

| Product Dimensions | L*W*H:3000*3000*2500mm | |

| Rated Power | <32.5kw | <56.6kw |

| Voltage | Three-phase five-wire 380 VAC | |

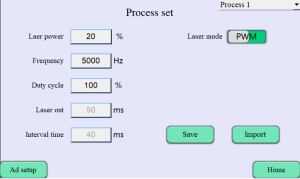

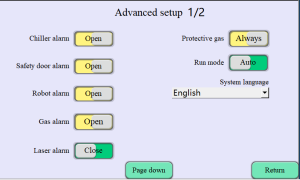

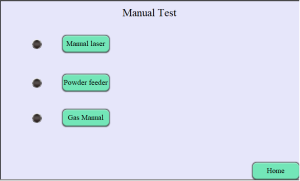

Control system

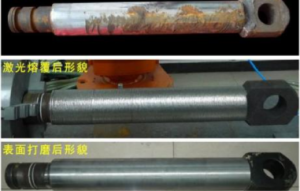

Application effect