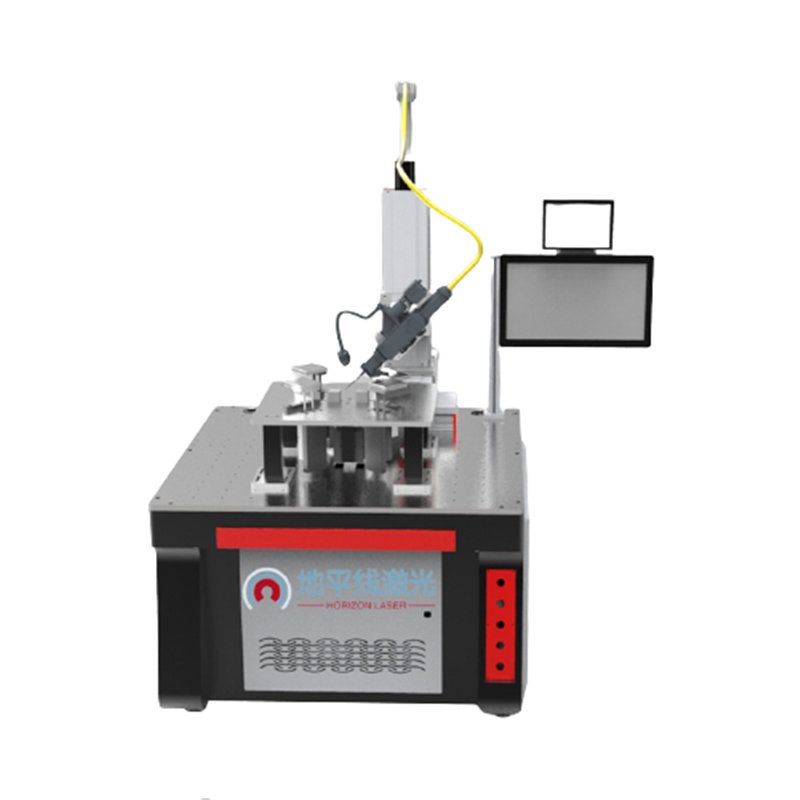

Description

Technical Parameters

| Laser | CW fiber laser, QCW laser |

| Laser power | 1000-6000W |

| Motion axis | 4- axis ( 3- axis, 5- axis, 6- axis optional), rotation axis |

| Welding head | Conventional welding head, swing welding head (weld seam 0.2 ~ 5 mm ) |

| Welding mode | Continuous welding (sealed welding, stitch welding, tailor welding, fillet welding), spot welding |

| Processing range | Length, width and height: 200-900mm (larger size can be customized) |

| Drive method | Servo motor (linear motor optional) |

| Repeatability | ± 0.03mm |

| Other optional configuration | Double station, CCD positioning, conveyor belt loading and unloading machine, wire feeding mechanism |

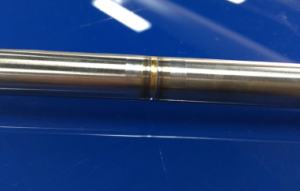

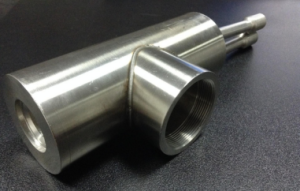

Apply effects

It has a high degree of flexibility and can meet the welding needs of any complex work piece. It is widely used in the automotive industry and electrical cabinet industry.