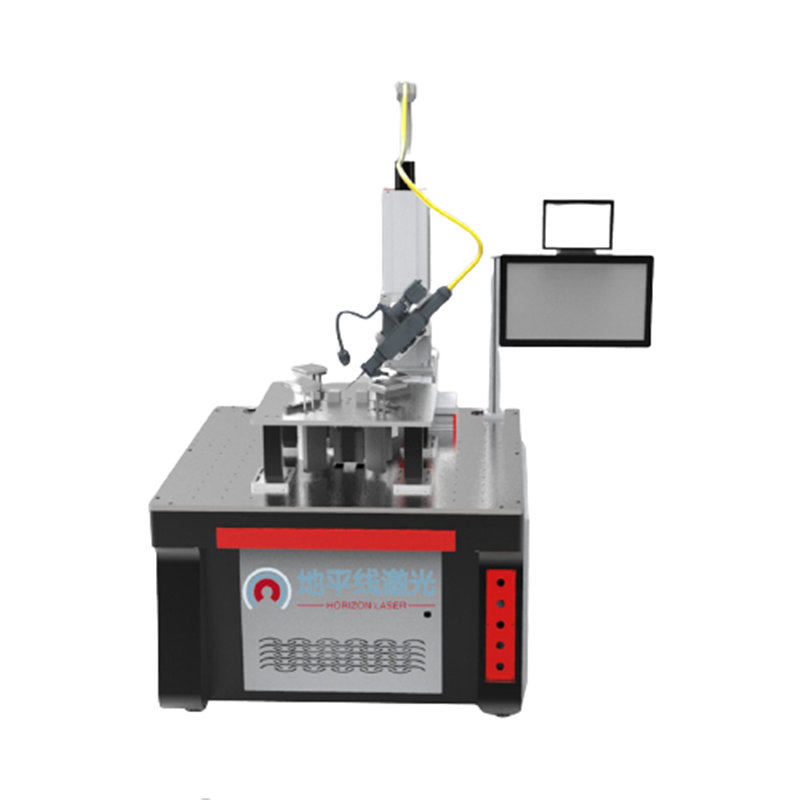

Well-designed 1500w Laser Welder - 3D Robot Laser Welding Machine – Horizon

Well-designed 1500w Laser Welder - 3D Robot Laser Welding Machine – Horizon Detail:

Robot welding workstation

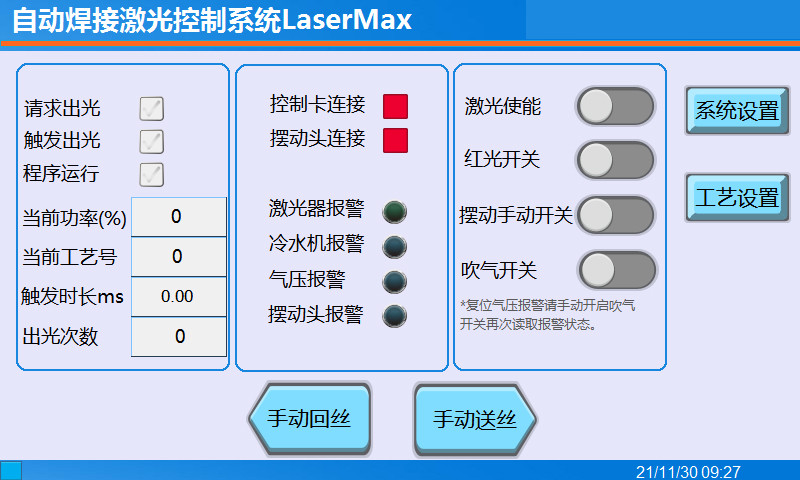

1. The manipulator does not need a laser signal module, and the direct IO signal communicates with the welding machine handshake;

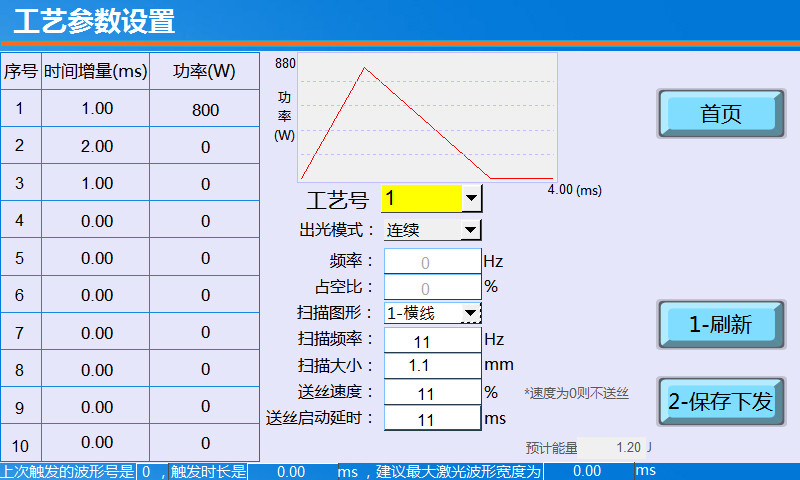

2. There are 64 sets of welding process waveforms, which are stored and recalled for welding requirements of different parts of the product;

3. The welding machine integrates functions such as laser control, swing welding head, wire feeding, and air pressure detection;

4. Realize offline multi-document welding processing to avoid incorrect welding caused by computer card machine;

5. Multi-signal closed-loop transmission of laser, laser control unit and manipulator, safe and reliable

Welding Settings

Technical Parameters

| Laser | Continuous Fiber Laser |

| Laser power | 1000-6000W |

| manipulator | 6 axis (multi-brand optional) |

| Welding head | Conventional welding head, galvanometer type swing welding head (weld seam 0.2 ~ 5 mm ) |

| Process waveform | 64 groups ( IO port call) |

| Waveform function | Laser power, pulse width, start and end arc control, swing length, swing type, wire feed |

| Load-bearing load | 8-20kg (specification optional) |

| Processing radius | 500-2000mm (Specifications are optional) |

| Targeting | Red light indication + CCD vision |

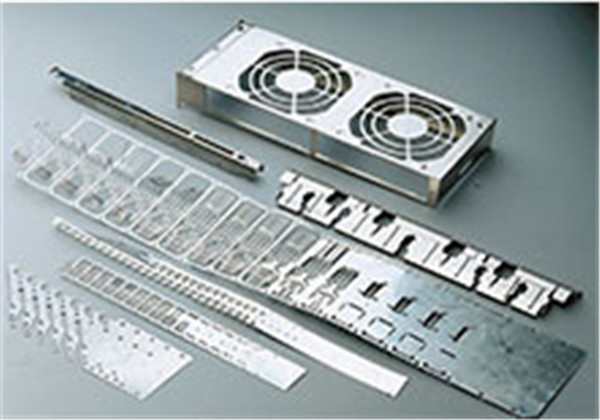

Application Area

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Well-designed 1500w Laser Welder - 3D Robot Laser Welding Machine – Horizon , The product will supply to all over the world, such as: Zambia, Sacramento, United States, To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.

Write your message here and send it to us

Products categories

-

E-mail

-

WhatsApp

-

Wechat

Wechat

18823836110

-

Top