100-300W Pulse Laser Cleaning Machine

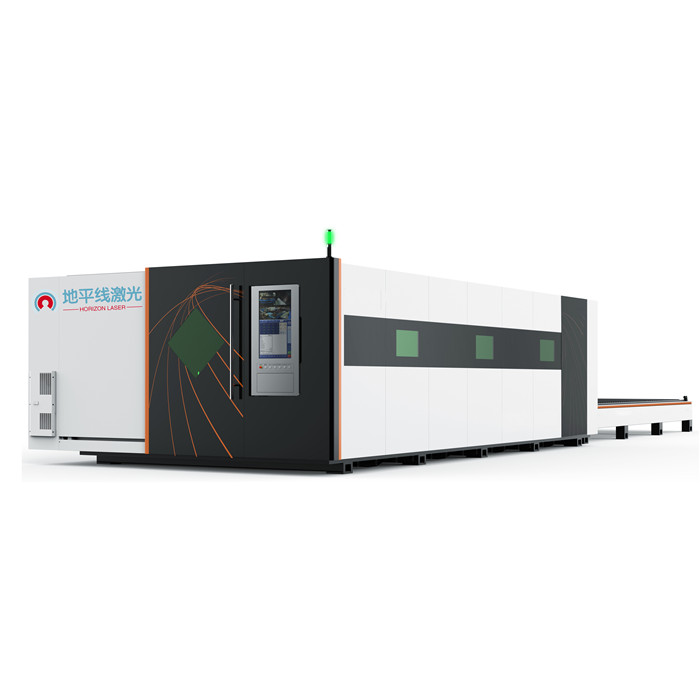

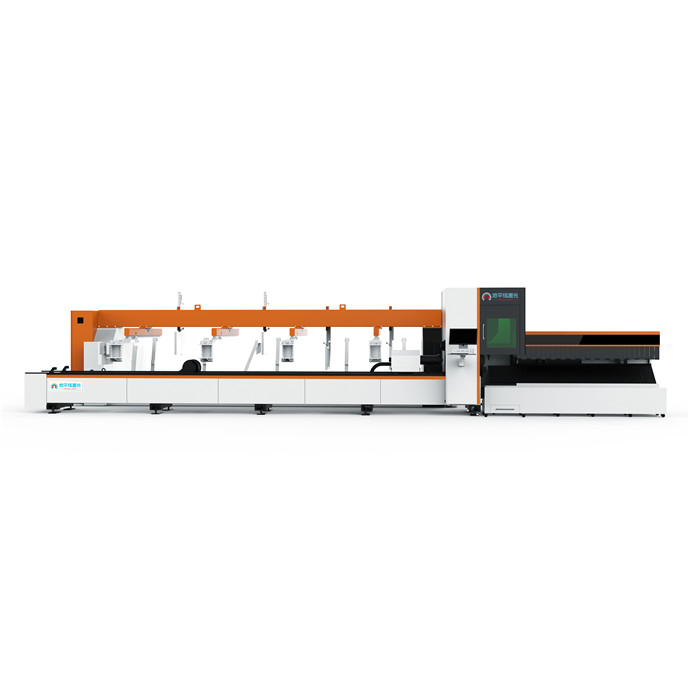

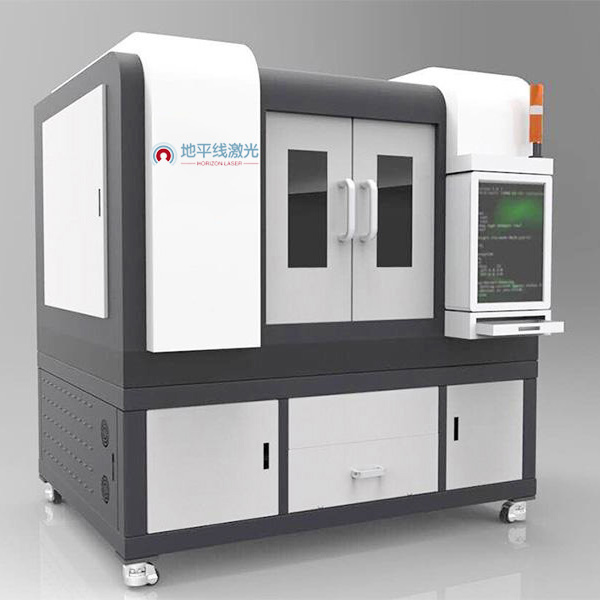

Machine structure

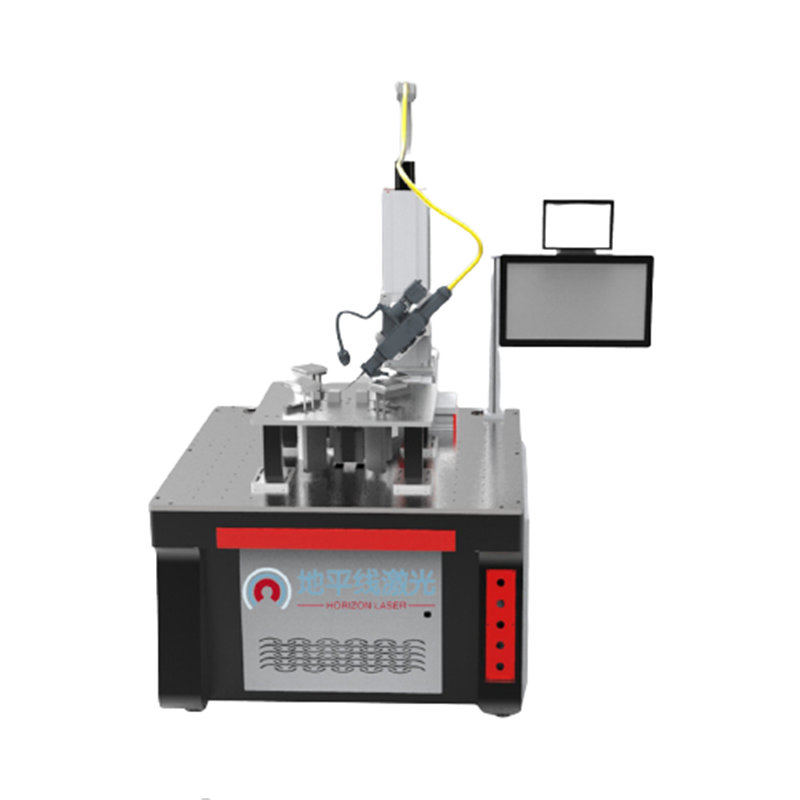

Cleaning head structure

Technical Parameters

Item

Characteristics

Typical Value

unit

Electrical Characteristics

Supply Voltage

220V (customizable 110V)

V

Maximum Power Consumption

550@100W、950@200W、1350@300W

W

General Characteristics

Laser Power

100-300

W

Laser Wavelength

1064

nm

Maximum Single Pulse Energy

1.5@100W、5@200W、5&15@300W

mJ

Fiber Cable Length

5m (customizable 10m)

m

Cooling Method

Air Cooling

Adjustable Cleaning Width

120mm@F300、100mm@F254

mm

Cleaning Head Weight

<1.3

kg

Product Size

L*W*H:543*325*580

mm

Total Weight

30-35

kg

Machine structure

|

Item |

Characteristics |

Typical Value |

unit |

|

Electrical Characteristics |

Supply Voltage |

220V (customizable 110V) |

V |

|

Maximum Power Consumption |

550@100W、950@200W、1350@300W |

W |

|

|

General Characteristics |

Laser Power |

100-300 |

W |

|

Laser Wavelength |

1064 |

nm |

|

|

Maximum Single Pulse Energy |

1.5@100W、5@200W、5&15@300W |

mJ |

|

|

Fiber Cable Length |

5m (customizable 10m) |

m |

|

|

Cooling Method |

Air Cooling |

|

|

|

Adjustable Cleaning Width |

120mm@F300、100mm@F254 |

mm |

|

|

Cleaning Head Weight |

<1.3 |

kg |

|

|

Product Size |

L*W*H:543*325*580 |

mm |

|

|

Total Weight |

30-35 |

kg |

Product Features

- The solution combines a pulsed laser with a dual oscillating mirror cleaning head. Compared to continuous laser cleaning, it features lower heat input, higher peak power, and stronger penetration, making it more suitable for cleaning precision products with delicate and refined results.

- The dedicated cleaning laser ensures uniform beam energy distribution, delivering a fine cleaning effect without damaging the substrate and leaving no underlying patterns.

- The cleaning head utilizes an ultra-high-speed dual oscillating mirror, enabling more efficient and thorough cleaning.

- The cleaning width can reach up to 120mm @ F300 (100mm @ F254), meeting the requirements for efficient cleaning of large-sized products.

- It comes with 9 sets of cleaning process parameters and 8 types of cleaning trajectory patterns, which can be directly applied to clean different products.

- The cleaning head can be switched between handheld and fixed modes, catering to a wider range of cleaning scenarios.

- With long-distance fiber transmission, it supports mobile operation and can clean large fixed equipment, products with complex shapes, and hidden areas.

- It is capable of cleaning a wide range of materials, including rust, coatings, rubber, paint, resin, oil stains, and more.

Cleaning Efficiency

|

200W Pulsed Laser Cleaning Machine |

||

|

Cleaning Material |

Thickness |

Cleaning Efficiency |

|

Surface Rust |

50μm |

10-15m2/h |

|

Iron Rust |

120μm |

4-6m2/h |

|

Paint |

100μm |

2.5-4m2/h |

|

Note: The above cleaning efficiency is for reference only. Actual results may vary based on product testing. |

||

Application Cases

Cleaning Machine

Fiber Laser Cleaning Machine

High Quality Laser Clenaing Machine

Laser Cleaning Machine

Oem Cleaning Machine

Rust Removal Machine Price,Small size

Mold cleaning

Products categories

-

E-mail

-

WhatsApp

WhatsApp

-

Wechat

Wechat

18823836110

-

Top