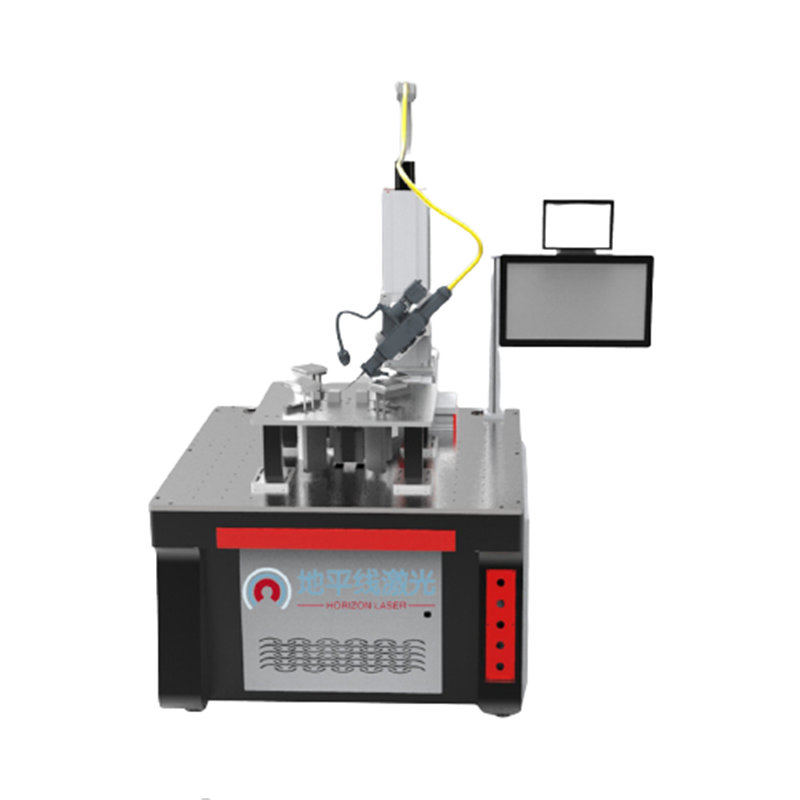

Handheld laser spot welding machine

Product structure:

Machine technical parameters:

|

Device model |

DPX-P800 |

DPX-P1200 |

DPX-P1500 |

|

Laser type |

Fiber laser (wavelength 1080±3nm) |

||

|

Peak power |

800W |

1200W |

1500W |

|

cooling method |

Air cooling |

||

|

Power adjustment range |

10%~100% |

||

|

Welding mode |

Spot welding |

||

|

Welding gun cable length |

Around 9.0m |

||

|

Welding gun weight |

0.45kg |

||

|

Welding gun size |

L:139mm φ:39mm |

||

|

Product Size |

L*W*H:543*325*580mm |

||

|

Total Weight |

32kg |

32kg |

36kg |

|

Machine power consumption |

<2.5kw |

<3.7kw |

<4.6kw |

|

Operating Voltage |

Single phase three wire 220VAC |

||

|

Working environment requirements |

Temperature: 0~40℃, humidity <70% |

||

Product features:

Pulse laser welding is used to compare continuous laser welding to ensure that the heat input is small under high peak laser energy and thin plate welding will not be welded through.

The output pulsed laser spot frequency can reach 10KHz, with a welding speed of up to 200mm/s.

Adjusting different pulse widths and focal positions meets requirements for different weld spot sizes.

Adjust different pulse laser frequencies to meet different welding joint overlap rates and achieve high-speed handheld mobile welding.

The handheld welding joint is lightweight and has a size comparable to the palm, which meets long-term and easy welding operations.

The welding process is simple, and the gun head is assisted in aligning the welding position. It can be welded by dragging, which is easy to get started.

Welding performance:

|

Device model |

DPX-P800 |

DPX-P1200 |

DPX-P1500 |

|

Stainless steel |

≤1.0mm |

≤1.5mm |

≤2.0mm |

|

Low-carbon steel |

≤1.0mm |

≤1.5mm |

≤2.0mm |

|

galvanized sheet |

≤1.0mm |

≤1.5mm |

≤2.0mm |

|

Aluminum alloy |

≤0.8mm |

≤1.0mm |

≤1.5mm |

|

Brass |

≤0.8mm |

≤1.0mm |

≤1.5mm |

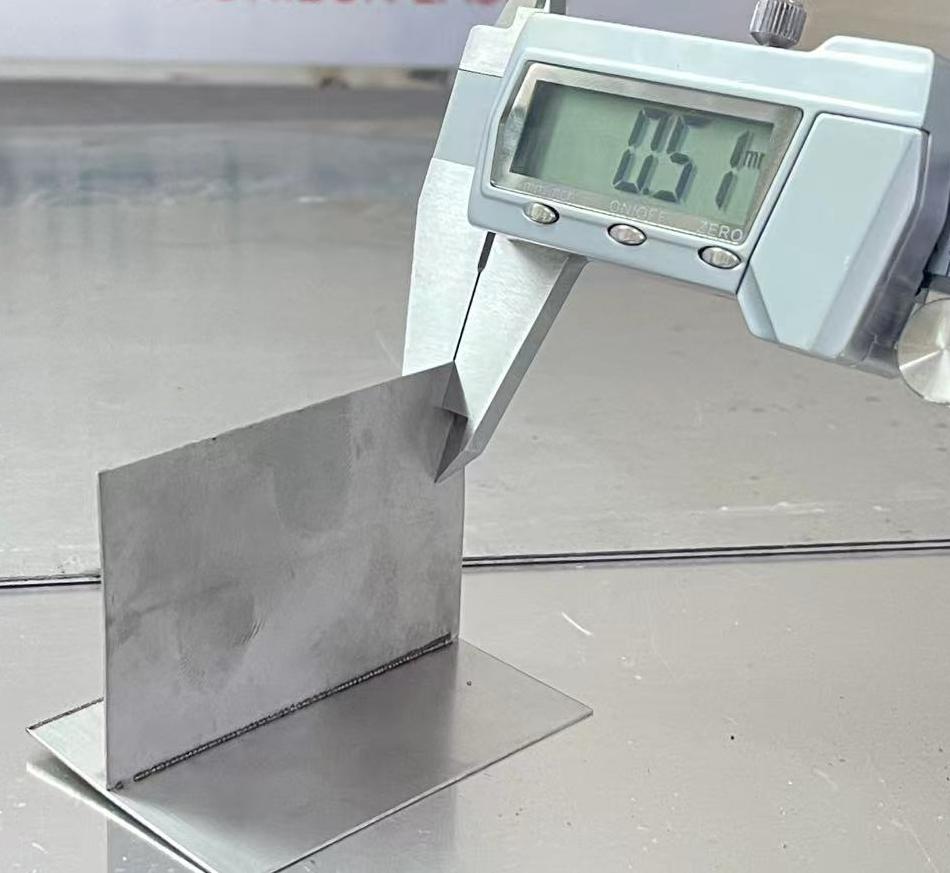

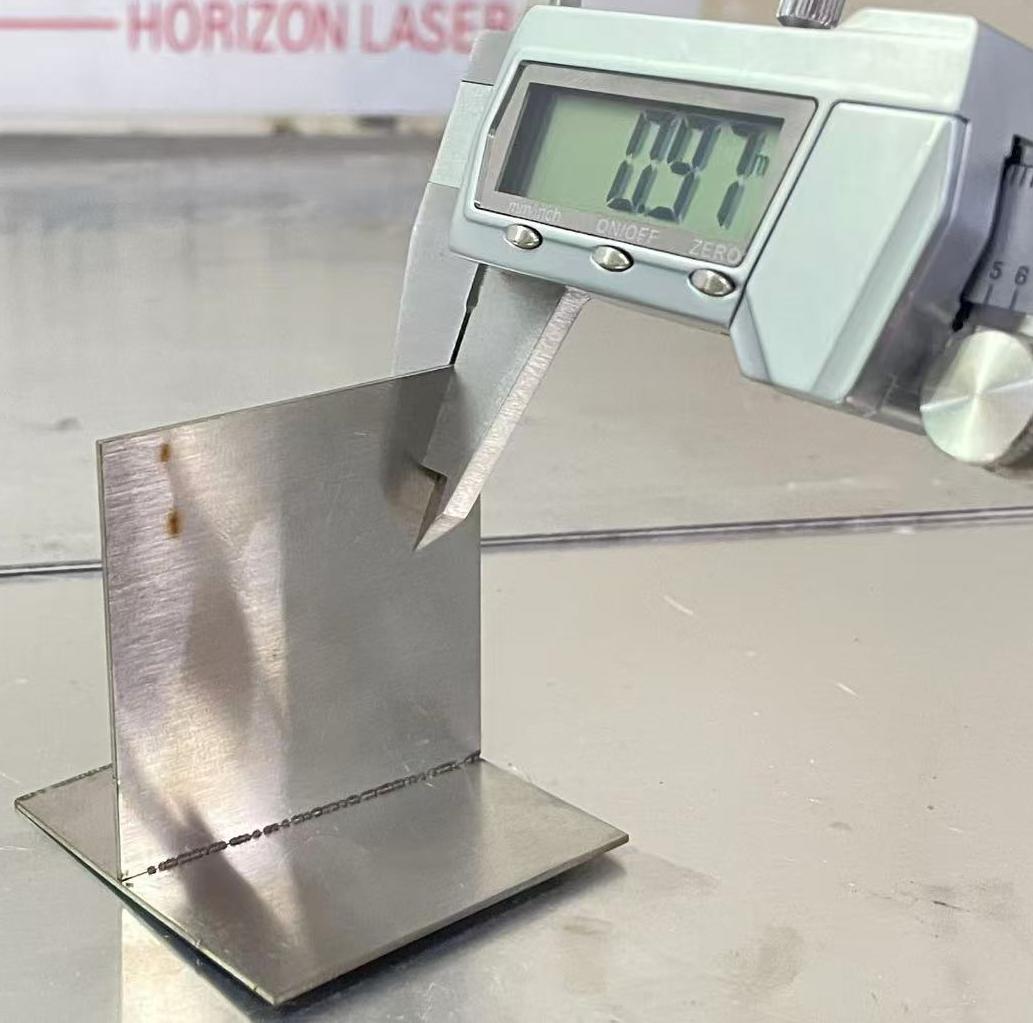

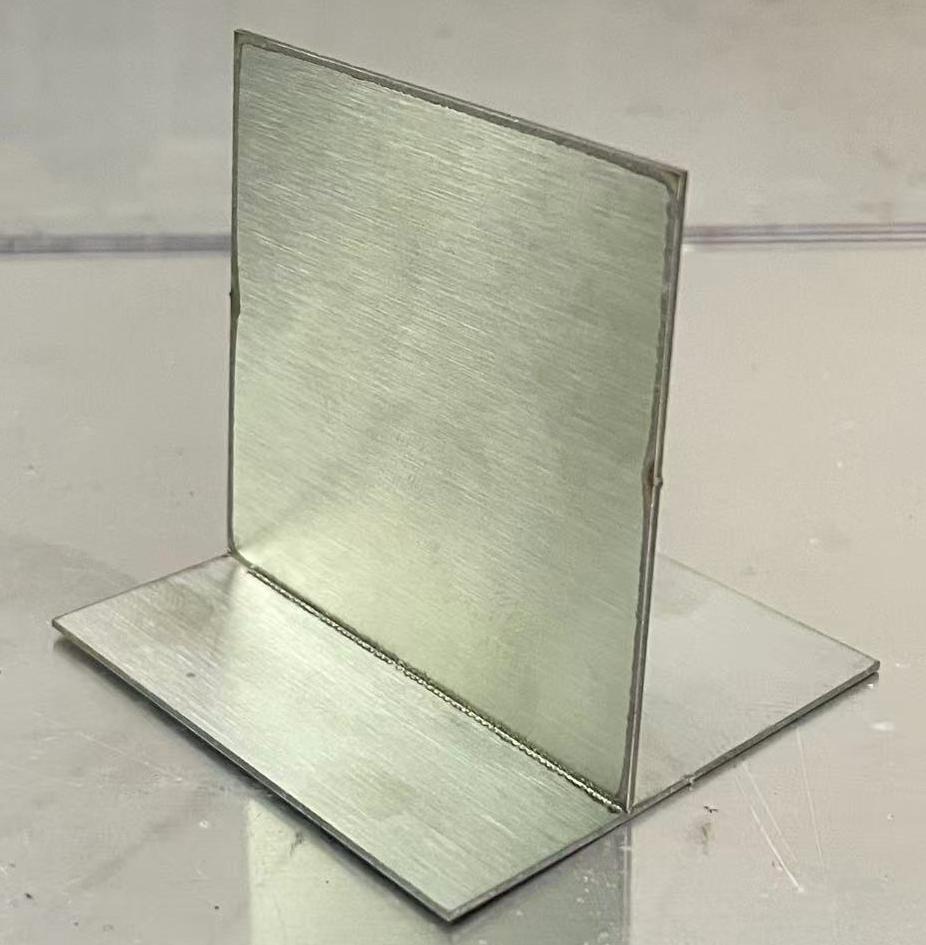

0.2-1mm thin plate welding

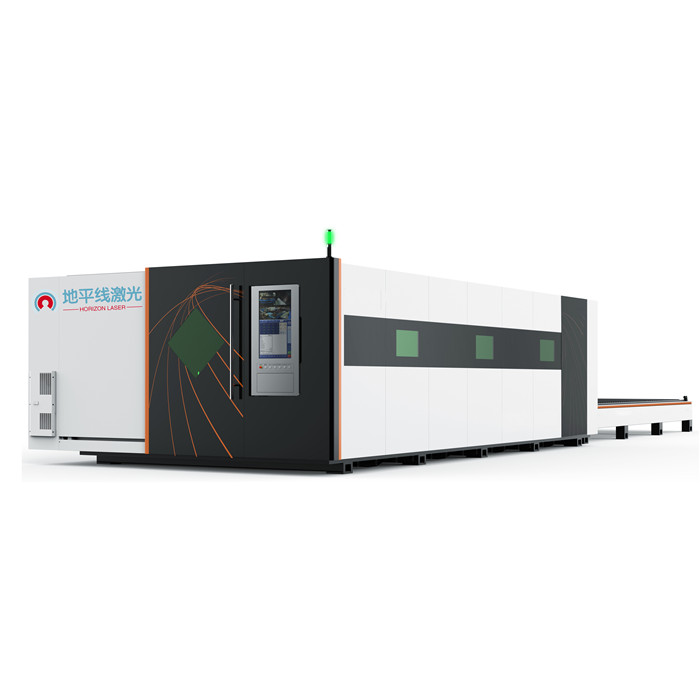

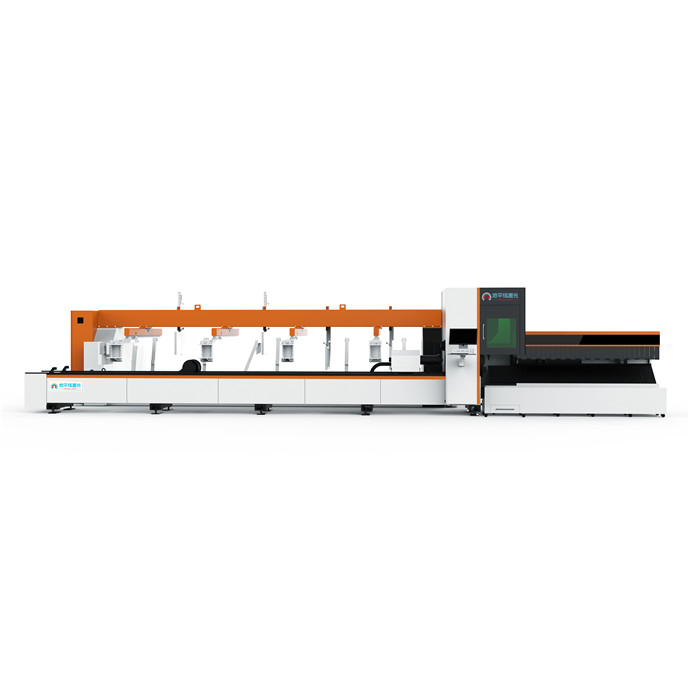

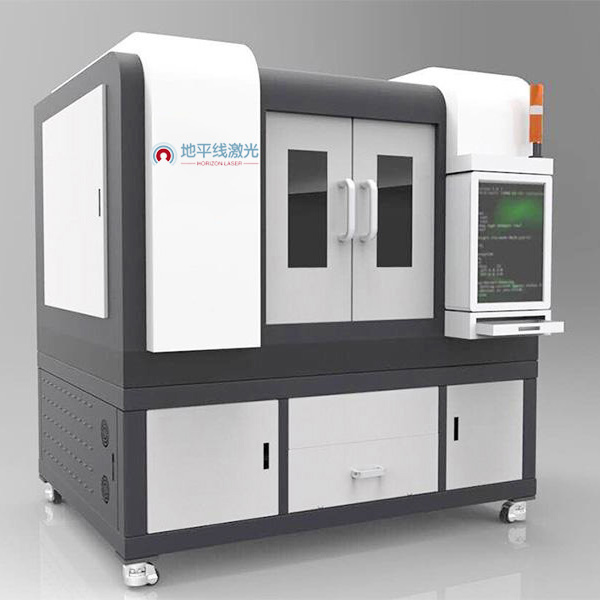

Thin Sheet Laser Welding Machine

Handheld laser spot welding machine

0.2-2mm thin plate welding

Products categories

-

E-mail

-

WhatsApp

WhatsApp

-

Wechat

Wechat

18823836110

-

Top