Products

-

Air cooled handheld laser welding machine

The air-cooled handheld laser welding machine is a high-power laser welding device newly launched by Horizon Laser Technology Co., Ltd. The entire machine adopts an air-cooled structure, with a compact size and easy mobility, meeting the needs of more application scenarios. The handheld mode facilitates the welding of products such as boilers, cabinets, doors, windows, and advertising signs, making laser welding possible for outdoor operations. It is set to replace most applications of traditional electric welding and argon arc welding. The air-cooled handheld laser welding machine integrates an air-cooled laser, handheld welding gun, wire feeder, laser control system, and safety light emission system into one unit. It can stably and continuously emit light for welding, enabling butt welding, lap welding, seal welding, seam welding, and spot welding of products. -

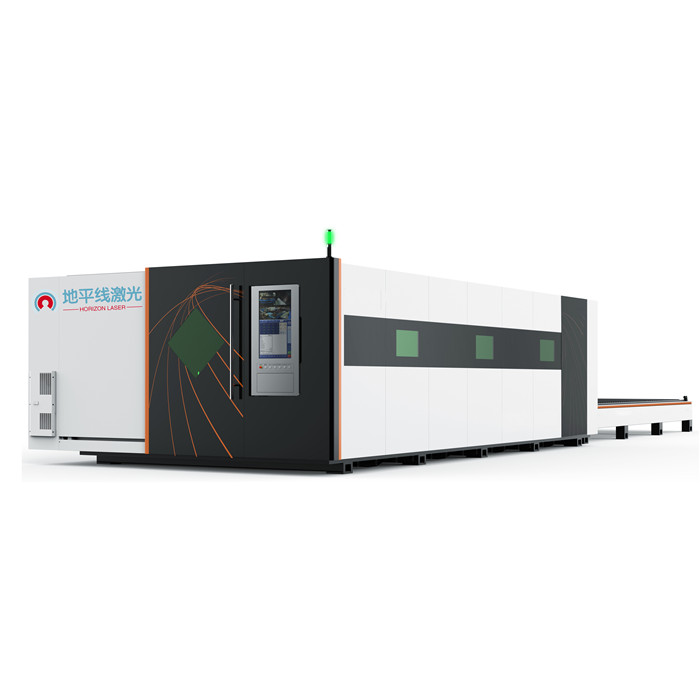

Exchange table laser cutting machine 1000-30000W

Exchange table laser cutting machine comes with high processing efficiency. It adopts imported servo double-drive rack and pinion structure, parallel interactive worktables, and fully enclosed sheet metal outer protection. It is a laser cutting machine with superior performance and high-efficiency processing. Suitable for external processing or exclusive industry customer groups (aluminum sheet). -

Handheld laser welding machine

The hand-held laser welding machine features a compact structure and easy mobility, catering to a wider range of application scenarios. Its handheld mode facilitates the welding of products such as boilers, cabinets, doors, windows, and advertising characters, making laser welding possible for outdoor operations. It is set to replace the majority of applications traditionally served by electric welding and argon arc welding. The complete set of the handheld laser welding equipment mainly integrates a fiber laser, a handheld welding gun, chiller,a wire feeder, a laser control system, and a safe light emission system into one unit. It can deliver stable and uninterrupted light emission for welding, enabling butt welding, lap welding, seal welding, seam welding, and spot welding of products. -

Single platform laser cutting machine 1000-30000W

Single platform laser cutting machine The single-platform laser cutting machine has a small overall footprint and high cost performance. As an economical and practical laser cutting machine, it can be used by the majority of medium and thin plate customers who pursue quality and have limited budgets. -

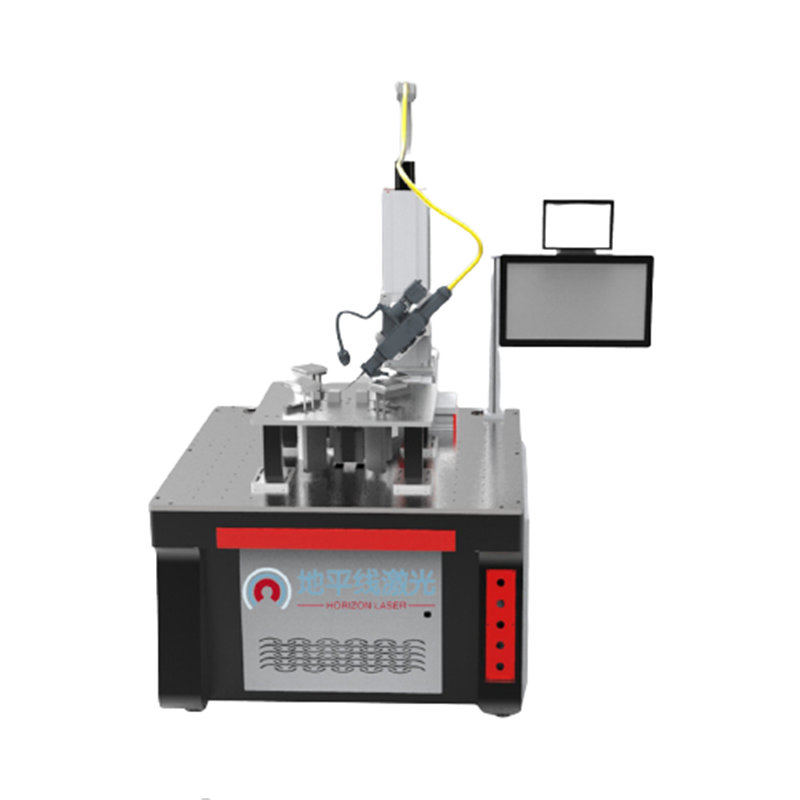

Handheld laser spot welding machine

The handheld laser spot welder is a newly launched welding equipment by Horizon Laser Technology Co., Ltd., specifically designed for thin sheets ranging from 0.2 to 2mm. The entire machine adopts an air-cooled structure, featuring a compact size and easy mobility to meet diverse application scenarios. With its lightweight welding head and handheld operation, it is ideal for welding products such as doors and windows, advertising letters, lampshades, and metal housings of household appliances. The air-cooled handheld laser spot welding system integrates a complete set of components, including an air-cooled laser, handheld welding gun, laser control system, and safety beam emission system. It ensures stable and uninterrupted laser welding, enabling various welding techniques such as spot welding, butt welding, lap welding, seal welding, and seam welding on products. -

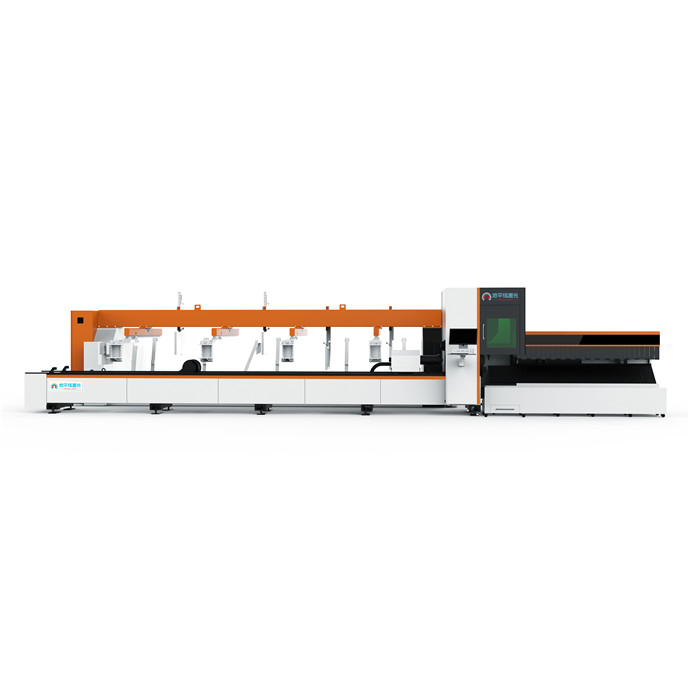

Pipe laser cutting machine

The pipe laser cutting machine can cut various pipes such as square pipes, round pipes, special-shaped pipes, etc. It is mainly used for shelves, vehicle frames, sports equipment, pipes and other industries. Various shapes such as intersecting lines, special-shaped holes and square holes can be cut on the pipe. According to different customer needs, it is divided into manual feeding pipe cutting machine and automatic feeding pipe cutting machine. The manual feeding cutting machine is suitable for occasions where the size of the pipe is large and the processing time of a single tube is long; the automatic feeding cutting machine is suitable for the occasions where a large amount of products are processed in large quantities, the product types are relatively single, and the cutting efficiency is required. -

Multi-axis laser welding machine

Multi-axis laser welding machine controls the movement of the welding head through multiple motion axes, realizes multi-track welding of complex products, and is suitable for application scenarios with high welding precision and batch product processing. It is widely used in lithium battery industry, 3C industry, kitchen and bathroom industry. -

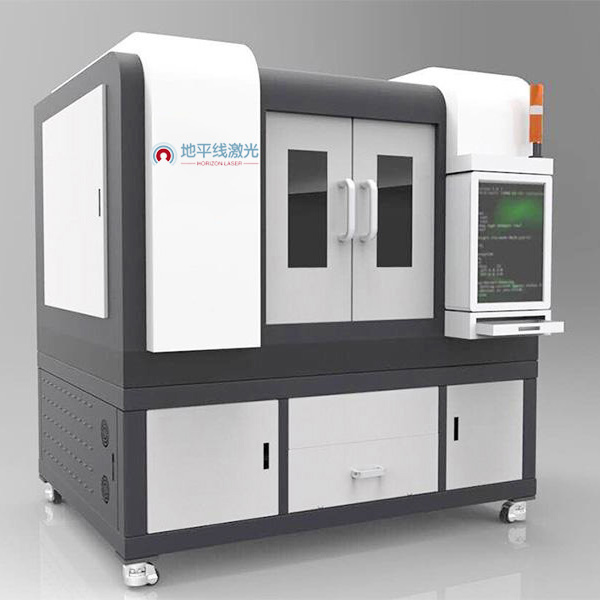

Precision Laser Cutting Machine

The precision laser cutting machine can realize the laser fine processing of metal and most non-metallic sheets, and is suitable for occasions with high requirements on cutting precision and small size of cutting products. It can meet the precision machining of cutting, drilling, scribing and so on at the same time. The application market is gold and silver materials for the jewelry industry, aluminum substrates and copper substrates for the circuit industry, PCD synthetic diamonds for the tool industry, and high-hardness steel for saw blades. -

3D Robot Laser Welding Machine

3D robot laser welding machine through the laser control module and the manipulator motion mechanism, match each other and work together. It has a high degree of flexibility and can meet the welding needs of any complex work piece. It is widely used in the automotive industry and electrical cabinet industry. -

100-300W Pulse Laser Cleaning Machine

The pulsed laser cleaning machine utilizes a laser specifically designed for cleaning, enabling non-contact cleaning operations. The laser is transmitted through an optical fiber and paired with a handheld cleaning head, allowing for flexible and oscillating cleaning. The handheld cleaning head can also be integrated with automated production lines, facilitating efficient and large-scale cleaning and refurbishment of products. The pulsed laser cleaning machine features a cleaning head with a dual oscillating mirror structure, delivering high peak laser power, substantial single-pulse energy, and uniform beam energy distribution. Compared to traditional cleaning methods such as dry ice, chemical etching, and sandblasting, it offers advantages such as no damage to the product substrate, minimal heat input, no consumables, and no pollution. It can effectively remove rust, coatings, rubber, paint, resin, oil stains, and other contaminants from product surfaces. This machine is primarily used in industries such as mold manufacturing, mechanical component refurbishment, rail transportation, shipbuilding, petrochemical pipelines, automotive manufacturing, and cultural heritage restoration. -

500W Pulse Laser Cleaning Machine

The pulsed laser cleaning machine utilizes a laser specifically designed for cleaning, enabling non-contact cleaning operations. The laser is transmitted through an optical fiber and paired with a handheld cleaning head, allowing for flexible and oscillating cleaning. The handheld cleaning head can also be integrated with automated production lines, facilitating efficient and large-scale cleaning and refurbishment of products. The pulsed laser cleaning machine features a cleaning head with a dual oscillating mirror structure, delivering high peak laser power, substantial single-pulse energy, and uniform beam energy distribution. Compared to traditional cleaning methods such as dry ice, chemical etching, and sandblasting, it offers advantages such as no damage to the product substrate, minimal heat input, no consumables, and no pollution. It can effectively remove rust, coatings, rubber, paint, resin, oil stains, and other contaminants from product surfaces. This machine is primarily used in industries such as mold manufacturing, mechanical component refurbishment, rail transportation, shipbuilding, petrochemical pipelines, automotive manufacturing, and cultural heritage restoration. -

Mold laser cleaning workstation

The laser cleaning workstation is a set of intelligent and environmentally friendly automated laser cleaning equipment, used for offline fully automatic laser cleaning of semi-steel tire mold blocks and side panels. This product uses machine vision to identify and locate dispersed molds. Intelligently identify the positions of the blocks and side panels, and clean the roots and rubber-spill areas of the blocks without disassembling the blocks. The system comes with a vacuum cleaner to filter and collect smoke, irritating or harmful gases generated by cleaning tire molds, which can reduce the spread of irritating or harmful gases in the air and cause environmental pollution and reduce the impact on people's health. The intelligent laser cleaning workstation of tire molds consists of a laser cleaning system, a water cooling system, a robot system, a servo motion platform, a 3D visual positioning system, an operation control system, a vacuum cleaner system, a laser safety room and a monitoring system. -

Fiber Laser Marking Machine

Laser marking machines use laser beams to mark permanent patterns, trademarks and characters on the surface of various materials. Laser marking machines are mainly divided into fiber laser marking machines, UV/green laser marking machines, and CO2 laser marking machines etc. Widely used in the industry of electronic components, electrical appliances, mobile communications, hardware products, tool accessories, precision equipment, jewelry, auto parts, plastic buttons, building materials, PVC pipes. Fiber laser marking machines use laser beams to act on product surfaces of different materials, marking out characters, patterns, QR codes and other contents without consumables. Fiber laser marking machine has high power and is most suitable for surface engraving of metal components, hardware products, 3C products, deep engraving, and can also mark surface engraving of plastic non-metal products. Horizon Laser mainly produce 20W/30W/50W/100W desktop, portable, mini and hand-held fiber laser marking machines. -

UV Laser Marking Machine

The laser marking machine uses a laser beam to engrave characters, patterns, QR codes, and other content on the surfaces of various materials without the need for consumables. The UV laser marking machine employs cold light processing, making it ideal for engraving on plastic products such as ABS, PP, and wires. It is also suitable for marking on surfaces like stone, jade, metal components, and hardware products.